> FX MOTOR BRAIN

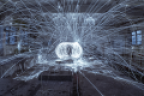

FX Motor Brain provides intelligent PHM services for industrial low-voltage motors through the combination of sensor boxes and SaaS application platforms. The sensor supports mobile APP Bluetooth connection and configuration, and supports multi-network and multi-scenario access to SaaS application platforms such as Wi-Fi/ LORA/ 5G. The SaaS application platform uses the hybrid algorithm of AI and industrial mechanism to build the motor fault model library. With the help of data science technology, turn post-repair into pre-forecast.

Predictive maintenance solutions for general-purpose equipmen

Unexpected downtime, lack of maintenance, and excessive maintenance will bring invisible losses. However, the damage of the motor is a process that can be prevented and predicted! Vibration, temperature and other changes can reflect the state of the equipment and potential problems, FX Motor Brain can help users track the industrial low-voltage motor health status, understand the motor operation capacity.

> FX MOTOR BRAIN · HARDWARE

The box requires no interface and can be installed non-invasively to collect and analyze data directly. When the connection to the FX Motor Brain SaaS application is interrupted, the internal flash memory holds data for at least 48 hours.

No connection required, and can be installed on the motor surface without penetration

FX Motor Brain sensor box can be mounted directly on the motor surface, and the simple and exquisite shape brings powerful parameter acquisition capability and long-lasting battery life. It is suitable for working environment with temperature range of -40℃ to +80℃ and ambient humidity of 5% to 95%(no condensation). It has a wide range of application scenarios in various industries.

> FX MOTOR BRAIN · SAAS APPLICATION

The platform provides expert experience as the default alarm threshold for reference, and can be set by the user independently. Clear visual charts, map distribution summary, maintenance information tracking and various hardware management lists comprehensively improve efficiency of all users.

The predictive maintenance of the motor is truly realized with the system

The database is built on our exclusive cooperation —— 20 years of experience of vibration analysis experts and motor experts two team database, which realize the motor fault diagnosis and prediction accuracy of more than 95% . At the same time, the system reveals the causes of various failures, and turns the black box model into "white box", which is convenient for operation and maintenance, and greatly reduces the burden of maintenance personnel and spare parts.

> OTHER STANDARDIZED PRODUCTS

Common industrial hardware and software which can be inserted on the spot

Serves the factory scene with high behavioral safety requirements, and the deep learning algorithm based on AI neural network can calculate and identify various abnormal actions and behaviors, which can be used to ensure and manage factory safety, and monitor and identify violations.

In addition to realizing the docking of weighing, receiving and payment, report and file management, it can also be customized to realize the docking with the company’s ERP system. Safely and efficiently improve the efficiency of enterprise transportation related work.

Used for data collection standardization, fully in line with the industrial, energy and other industries based on the distributed data acquisition and transmission needs of the Internet of Things technology, to provide a complete wireless/Ethernet communication solution for various applications.

Other needs can call for details, let us achieve industry intelligence :)

D

Through data cleaning, modeling and analysis, valuable information contained in the data is found and universal rules are extracted to provide the optimal path for decision makers in optimizing production scheduling and mechanical operation. On the basis of realizing the above final goal, it also achieves the effect of data quality management, data security management, metadata management, etc.

- Basic Services & Analysis Algorithms -

instrumentation

Real-time state

workshop

analysis suite

products

equipments

materials

utility-type unit

- INDUSTRIAL CONSULTING -

√ Cooperate with Karlsruhe Institute of Technology (KIT) Global Advanced Manufacturing Institute (GAMI) to provide guidance of digital transformation of manufacturing enterprises.

√ GAMI provides customers with personalized solutions from research, training and consulting through the KIT platform and close cooperation with partners, to help customers achieve operational excellence and ensure the long-term and sustainable benefits.

。

INTELLIGENCE GUIDANCE

Beratung & ausbildung

- DIGITALIZATION TRAINING -