Digitalization of Cable & Wire

Digitalisierung der Kabel- und Drahtindustrie

D

CABLE PRODUCTION LINE DIGITALIZATION SOLUTION

WRITE A NEW CHAPTER OF THE INDUSTRY TOGETHER

The production method of continuous superposition combination makes the problem of any link affect the quality of the entire cable. More defects in the inner layer, the greater the loss caused by not timely suspension.

Difficulties of Quality Controlling

Low Data Utilization

P A I N

P O I N T

O F

T H E

INDUSTRY

Lack of effective data acquisition / storage / analysis methods and life-cycle maintenance. Equipment has been taken excessive / passive maintenance. Factories are suffered from inefficiency of management.

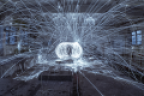

We use the Internet of Things and edge computing technologies to integrate and synchronize multi-source data in the production process, monitor the running status of the machine in real time, and create digital applications for wire and cable production.

F E N X I

SOLUTION

F O R

T H E

INDUSTRY

The services are based on the big data platform, which ensures the efficient operation of the cable production equipment. No need to worry about the stability, we will help you truly realize worry-free production.

Fenxi Case · Cable Production Digital Transformation

The practical Industry 4.0 solution for medium-sized manufacturing enterprises developed by ScaleIT, an Industry 4.0 innovation project of the German Ministry of Education, has been adopted for enterprises to achieve industrial Internet of things construction, industrial big data application, production scheduling optimization, material tracking and other services.

Developed and completed big data applications for digital intelligent transformation of production lines, including real-time production line (health) monitoring and tracking and automatic traceability of materials from order management to production processes and shipments.

|| Technical 1: Industrial Internet of Things construction

Lay optical fiber to build the required LAN, and deploy the required sensor network to realize the unified data acquisition, transmission, storage and management of the existing PLC system and the installed sensor.

|| Technical Indicator 2: Industrial big data application

Key Task Indicator: Completion of the IIoT Platform

|| Achieved the digital twin of the production shop

|| Developed workshop management and analysis software

Key Task Indicator: Production Scheduling Optimization Algorithm

|| Real-time optimized scheduling results are displayed in the form of Gantt chart and QR code, and information of materials and semi-finished products required for production is provided, which is synchronized with the material input and input of ERP

|| Able to merge orders and model optimal algorithms for products of different orders and mixed specifications in the same production line

Eliminate 80% of

unplanned downtime

Save 10%

overall cost

Improve 20% overall

efficiency