MODULIZATION OF FENXI DATA SERVICES / Ein modularer Datendienst

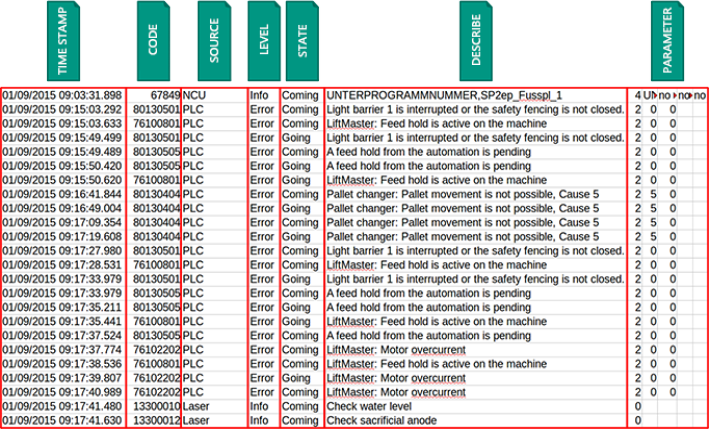

Real-time acquisition of monitoring parameters for each device and additional sensors

Through RFID/QR code and other technologies to achieve the production workshop machine interconnection

Cleaning, screening, sorting and categorizing a large number of chaotic structured and unstructured production data

Find out valuable hidden information from massive production data to help management make prediction

Optimization of scheduling, realize predictive maintenance, and so on

The situation of charging pile damage and failure often occurs, and there will be charging pile failure to charge but deduction of fees. In this context, Fenxi launched charging pile quality inspection & analysis software & algorithm to monitor as well as maintain the quality and safety of charging piles throughout the cycle from the production process to operation and charging process.

①Analyze the charging and pre-charging of the charging pile during actual operation, and monitor abnormal charging

②Data visualization, historical documents can be traced, easy to manage and subsequent optimization

③Efficient and energy-saving analysis process and detection,and algorithms backed by a lot of real data