Digitalization & Optimization of EAF Steelmaking

Energieeinsparung bei der Stahlerzeugung im Lichtbogenofen

D

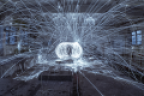

INTELLIGENT ENERGY SAVING SOLUTION FOR EAF:

HELP STEELMAKING TO AIM HIGH WHILE COST LOW

The steel industry accounts for 11% of China's energy consumption. With gradual upgrading of production restrictions and impact of dual-control policies, energy consumption has always been a hard pain point.

The Threat of Power Rationing and Production Restrictions

Low Profit of Electric Arc Furnace Steelmaking

P A I N

P O I N T

O F

T H E

INDUSTRY

The supply of raw materials is in tight-balanced condition for a long time, and the production cost continues to get higher while the industrial electricity costs a lot.

We provide steelmaking process information and energy saving solutions for steel enterprises, carry out comprehensive data mining and optimization of plant equipment, and develop dynamic optimization plans for steelmaking quality and energy saving. In addition to achieving substantial energy saving, the utilization of raw materials is significantly reduced. At the same time of cost reduction, customized visualization platform and optimization plan for furnace length intelligence are provided.

F E N X I

SOLUTION

F O R

T H E

INDUSTRY

Starting from the production process, it brings comprehensive energy saving and consumption reduction solutions;

Minimizing energy consumption at the end-operator without changing the production quality or affecting the production process.

Fenxi's core technology team comes from the Karlsruhe Institute of Technology (KIT, Germany). With years of solid experience in the industry and excellent academic background, Fenxi proposes a full-cycle smart solution for steel production from raw materials to finished products, which is carefully customized to address the industry's pain points such as high energy consumption, complex parameters involved in the process, and smelting information black box, etc., and protects the energy-saving of steelmaking.

ACHIEVEMENTS / DER EFFEKT

Monitoring&Optimization

of Production Process

Combine production information and data science to optimize process and flow control parameters in real time.

Material Location

and Tracking

Effectively trace raw material utilization, waste rate and impact on finished product quality.

Quality Optimization

of Finished Product

Effective control and optimization of finished product quality while saving energy and reducing emissions.